Belt drives are set to replace chains sooner than you think because they’re more durable, require less maintenance, and operate quietly. Thanks to advances in materials like reinforced fibers and smart designs, belts can handle heavier loads and resist elements like water and dirt better than chains. Their longer lifespan and eco-friendly benefits make them a smarter choice for many industries. If you keep exploring, you’ll discover how these innovations can benefit your system too.

Key Takeaways

- Modern belt materials offer higher strength, flexibility, and wear resistance, making them more durable than traditional chains.

- Belts require less maintenance, no lubrication, and have longer lifespans, reducing operational costs and downtime.

- Innovations like embedded sensors and self-tensioning systems enhance predictability and ease of belt drive upkeep.

- Belts operate more quietly and smoothly, improving user comfort and reducing mechanical wear.

- Advances in eco-friendly, lightweight composites and modular designs are accelerating belt drive adoption over chains.

The Evolution of Belt Drive Technology

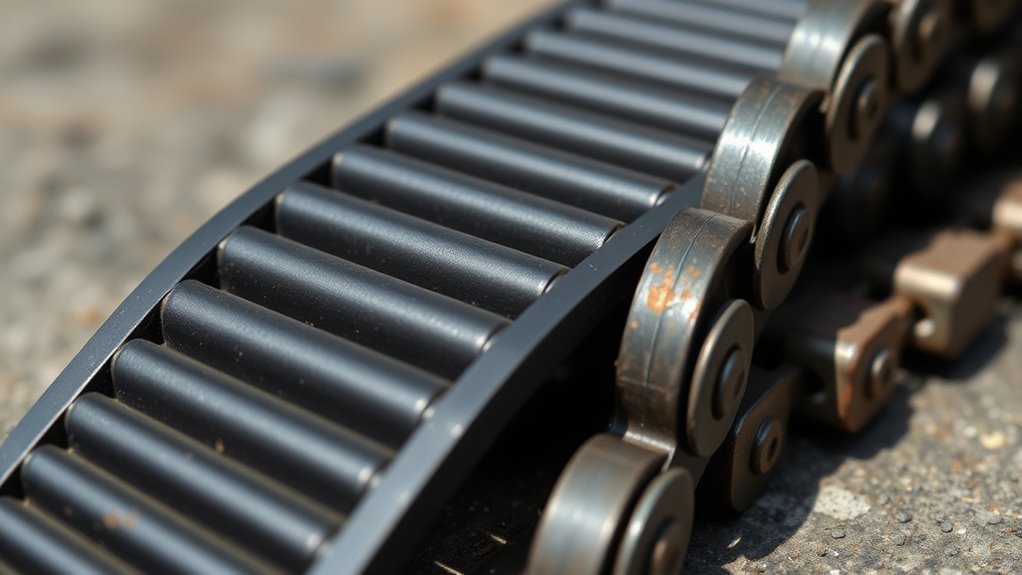

The evolution of belt drive technology has transformed how machines transmit power efficiently and reliably. Early belts used simple materials like leather, but advancements introduced synthetic belt materials such as neoprene, polyurethane, and rubber composites, greatly enhancing durability and flexibility. Modern manufacturing processes now produce belts with reinforced fibers and specialized coatings, improving strength and longevity. These innovations allow belts to withstand higher loads and operate smoothly over longer periods. Manufacturing techniques like extrusion, vulcanization, and precision cutting ensure consistent quality and performance. Over time, these improvements have led to belts that are more resistant to wear, slip, and environmental factors. As a result, belt drives have become more dependable, setting the stage for their increasing adoption in diverse mechanical applications.

Advantages Over Traditional Chains

Belt drives offer several advantages over traditional chains, making them a popular choice in modern machinery. One key benefit is improved chain durability; belts are less prone to stretching, wear, and damage over time, extending their lifespan. Unlike chains, which require constant lubrication to prevent rust and friction, belts have minimal lubrication needs, reducing maintenance efforts and mess. This low-maintenance nature makes them more convenient for continuous operation. Belts also operate more quietly and smoothly, decreasing noise levels and vibration. Their resistance to dirt and debris further enhances durability, especially in harsh environments. Additionally, understanding the relationships involved in machinery maintenance can help optimize belt drive performance and longevity. Overall, belt drives provide a more reliable, low-maintenance alternative that can outperform chains in durability and operational efficiency.

Reduced Maintenance and Longer Lifespans

With belt drives, you’ll notice you need to make fewer adjustments over time, saving you maintenance effort. Their components are built to last longer, resisting wear and tear better than traditional chains. This means your equipment stays reliable and requires less frequent repairs. Additionally, choosing proper maintenance practices can further extend the lifespan of your belt drive system. For example, selecting appropriate tensioning methods ensures optimal performance and reduces strain on components. Moreover, the integration of automation technologies in belt drive systems can optimize performance and reduce manual oversight. Regular inspections and correct installation techniques also contribute significantly to prolonging system durability. Incorporating preventive maintenance strategies helps identify potential issues early and keeps the system running smoothly.

Less Frequent Adjustments Needed

Because belts are less prone to stretching and wear than chains, they require fewer adjustments over their lifespan. You won’t need to frequently perform chain tensioning, saving you time and effort. Unlike chains, belts don’t require lubrication, which means you avoid regular lubrication requirements that can be messy and time-consuming. This reduction in maintenance means your belt drive system stays properly aligned longer, maintaining consistent performance. You’ll spend less time checking and adjusting tension, ensuring smoother operation without the constant concern of slack or tightness. Additionally, belts help reduce airborne pollutants that can be released during lubrication or maintenance activities, contributing to a cleaner environment. The material composition of belts often makes them more resistant to environmental factors like dirt and moisture, further extending their durability. Their resistance to contaminants is especially important in harsh operating conditions, where maintaining system integrity is crucial. Moreover, the cost-effectiveness of belts over time makes them a practical choice for many systems. Overall, belts offer a more reliable, low-maintenance solution that minimizes the need for frequent adjustments, helping you keep your system running efficiently with less intervention.

Extended Component Durability

Since belts require fewer adjustments and less maintenance than chains, they tend to last longer overall. Their wear resistance is superior because they don’t rely on metal-to-metal contact, reducing friction and abrasion. Unlike chains, belts don’t need lubrication, which means you avoid the mess and regular upkeep associated with lubrication requirements. This absence of lubrication also minimizes the risk of dirt and debris buildup that can accelerate wear. As a result, belts maintain their shape and tension longer, ensuring consistent performance over time. Their durability makes them ideal for applications demanding reliability and extended service life. Additionally, advancements in material technology have enhanced belt strength and flexibility, extending their service life even further. Understanding wear mechanisms helps in selecting the right belt for specific operational conditions, further improving longevity. Furthermore, modern manufacturing processes have contributed to improved belt uniformity and performance consistency, further boosting their lifespan. The use of reinforced fibers in belt construction has also played a crucial role in increasing their overall durability and resistance to extreme conditions.

Quieter Operation and User Experience

With belt drives, you’ll notice a significant reduction in noise compared to traditional chains, making your ride more enjoyable. The quieter operation also means less vibration, so you won’t feel every bump as much. This enhanced user experience allows for a smoother, more comfortable ride overall. Additionally, fabric decorating markers can be used to customize and personalize your bike accessories, adding a unique touch to your riding gear. Because belt drives require less maintenance and are more durable, they can also contribute to a more cost-effective cycling experience over time. Furthermore, the lubrication needs of belt drives are minimal, reducing the hassle of regular upkeep and ensuring consistent performance.

Silent Performance Enhancement

Switching to belt drives considerably reduces noise levels compared to traditional chains, creating a quieter operation that enhances your overall experience. The silence makes riding more peaceful and less disruptive, especially in quiet neighborhoods or early mornings. Plus, belt aesthetics add a sleek, modern look to your bike, making it stand out. With a variety of color options, you can customize your ride to match your style perfectly. Imagine:

- A smooth, matte black belt that complements your bike’s frame

- Bright, vibrant color options to make your bike pop

- Clean, streamlined design that eliminates greasy chains and dirt splatter

This quiet, stylish setup not only improves performance but also elevates your riding experience, making maintenance easier and your bike more visually appealing. Additionally, belt drives are known for their durability and longevity, requiring less frequent replacement compared to chains. Moreover, the low maintenance nature of belt drives means less time spent on upkeep and adjustments, allowing you to enjoy more riding and less servicing.

Reduced Vibration and Noise

Replacing traditional chains with belt drives considerably reduces vibration and noise during your ride, creating a smoother and more comfortable experience. Belt drives operate quietly because they generate less chain lubrication mess and eliminate the rattling sounds of sprocket wear. This quieter operation minimizes the vibrations felt through your handlebars, making your ride more pleasant. Over time, less sprocket wear means you won’t need frequent replacements, maintaining a quieter system longer. Additionally, advancements in AI safety measures are helping improve the design and durability of these systems, ensuring better performance and reliability. The efficiency of solar-powered systems in modern camping gear also contributes to the overall sustainability and convenience of using belt drive technology.

Environmental Benefits and Resistance to Elements

Belt drives offer notable environmental advantages over traditional chains by producing less noise and requiring fewer lubricants, which reduces the release of harmful chemicals into the environment. They’re often made from biodegradable materials that break down naturally, minimizing long-term waste. Plus, their resistance to elements like dirt, water, and corrosion means you spend less on maintenance and replacements. Imagine:

Belt drives are eco-friendly, quiet, durable, and require less maintenance, making them a greener choice for sustainable systems.

- A system that withstands rain and mud without rusting or slipping

- Reduced chemical runoff from lubricants contaminating soil and waterways

- Compatibility with solar-powered systems, reducing reliance on fossil fuels

These features make belt drives a greener choice, supporting sustainable solutions and lessening your ecological footprint. As the industry advances, their environmental benefits become even more compelling, promising a cleaner, more eco-friendly future.

Growing Industry Adoption and Innovations

As industries recognize the numerous benefits of belt drives, their adoption is growing rapidly across various sectors. Innovations focus on simplifying installation and maintenance, making belt drives more appealing. Manufacturers now emphasize precise sprocket alignment, reducing issues with chain tension and improving efficiency. This shift is driven by advancements like improved belt materials and tensioning systems, which enhance durability and performance.

| Industry Sector | Recent Innovation | Impact on Adoption |

|---|---|---|

| Manufacturing | Self-tensioning belts | Easier setup, fewer adjustments |

| Automotive | Lightweight composites | Better fuel efficiency |

| Food Processing | Food-safe belts | Hygiene compliance |

| Textile | High-flex belts | Increased longevity |

| Packaging | Quick-change systems | Reduced downtime |

Cost-Effectiveness Over Time

Over time, belt drives prove to be more cost-effective than traditional chain systems due to their lower maintenance requirements and longer lifespan. You’ll notice significant cost savings as belts don’t need frequent lubrication or tension adjustments. Plus, their quieter operation reduces the need for noise-related repairs. The installation ease of belt drives means less downtime and lower labor costs, allowing you to get equipment up and running faster. Imagine:

- A smooth, seamless setup that cuts installation time in half

- Fewer parts to replace, saving money on repairs

- Reduced operational costs thanks to durability and fewer adjustments

All these factors combine to make belt drives a smarter investment over the long run, delivering ongoing savings that add up quickly.

Future Trends and Potential Developments

Advancements in material science and engineering are driving the development of smarter, more efficient belt drive systems. These innovations aim to enhance durability, reduce maintenance, and expand applications across urban cycling and vintage machinery. Future trends include incorporating lightweight composites for increased strength and flexibility, enabling seamless integration into compact and retrofitted bikes. Additionally, smart sensors could monitor belt tension and wear, optimizing performance and longevity. The table below highlights potential developments:

| Technology | Application | Benefit |

|---|---|---|

| Carbon Fiber Composites | Urban bikes | Lighter, stronger belts |

| Embedded Sensors | Vintage machinery | Real-time wear monitoring |

| Self-Healing Materials | All types | Extended lifespan |

| Modular Designs | Custom setups | Easy maintenance and upgrades |

Frequently Asked Questions

How Do Belt Drives Compare to Chains in Extreme Weather Conditions?

In extreme weather conditions, belt drives often outperform chains because of their weather resilience and slip resistance. You’ll notice that belts handle moisture, mud, and cold better, reducing the risk of slipping or slipping. Chains can rust or freeze, making them less reliable. So, if you face harsh weather regularly, switching to a belt drive could keep your bike running smoothly and safely in any environment.

Are Belt Drives Suitable for High-Torque Industrial Applications?

Think of belt drives like a finely tuned orchestra—smooth and efficient. For high-torque industrial applications, you need a system built to handle the pressure. Belt drives excel here due to their material durability and impressive load capacity. They can manage heavy loads and harsh conditions, making them a reliable choice. If you prioritize longevity and performance, belt drives could be your best bet for demanding industrial tasks.

What Are the Limitations of Belt Drives in Current Machinery?

You should be aware that belt drives have limitations in current machinery. Material limitations can cause belts to wear out faster under heavy loads or harsh conditions, reducing their lifespan. Additionally, maintenance challenges, like proper tension adjustment and alignment, can be tricky, leading to slippage or failure. These factors may restrict their use in some applications, so you need to take into account these constraints before opting for belt drives over chains.

Can Belt Drives Be Easily Retrofitted Into Existing Systems?

Retrofitting belt drives into your existing system can be tricky due to compatibility issues and retrofitting challenges. You might need to modify mounts or adjust pulley sizes, which isn’t always straightforward. While some systems are designed for easy upgrades, others pose significant hurdles. It is crucial to assess your equipment carefully, ensuring compatibility and planning for potential modifications to successfully switch to belt drives.

How Do Belt Drive Materials Impact Overall System Performance?

Did you know that belt drive materials with higher durability can last up to 50% longer? Material durability directly impacts overall system performance by resisting wear and reducing maintenance needs. The friction coefficient also plays a vital role; low friction materials improve efficiency and reduce energy loss. Choosing the right belt material guarantees smoother operation, longevity, and ideal performance, making it important to take into account both durability and friction properties for your system’s success.

Conclusion

Think of belt drives as the steady river carving through time, outlasting the worn and brittle chain. As technology flows forward, these belts are becoming the dependable current, quietly guiding your machinery into the future. Embrace this evolution, and you’ll find your system sailing smoother and longer—leaving behind the turbulent rapids of traditional chains. The river of innovation is clear: belt drives are ready to lead you into a quieter, more durable tomorrow.