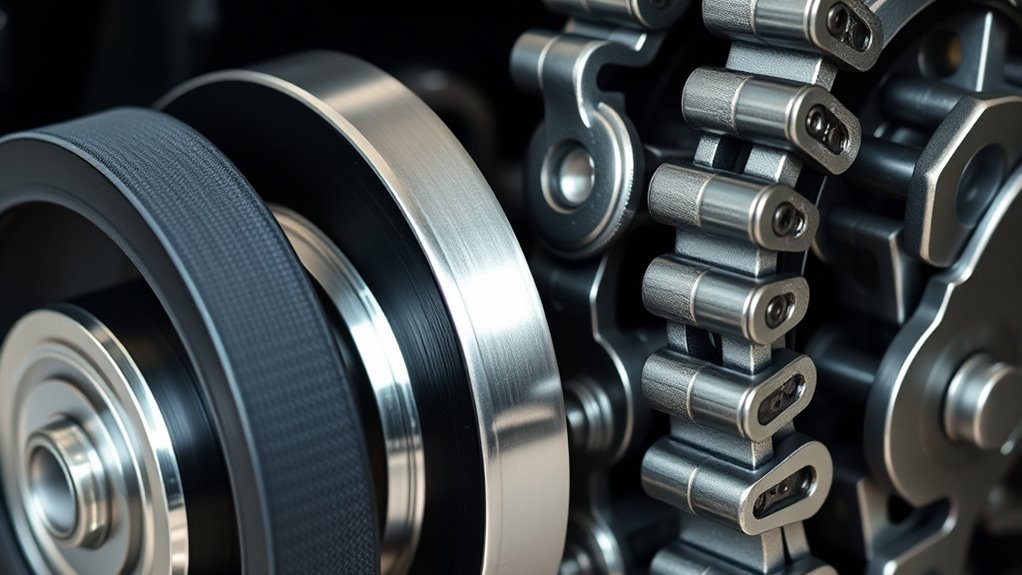

When choosing between belt drives and chains, consider your needs: belts operate quietly and are easier to replace, making them ideal for smooth, precision work, while chains handle heavier loads and harsh environments, offering higher efficiency and durability. Chains require more maintenance and can be noisier, but they’re better for demanding tasks. If you’d like to learn more about their pros and cons, you’ll find detailed insights to help you make the right choice.

Key Takeaways

- Chains handle higher loads and harsh environments better, offering greater durability and power transfer efficiency.

- Belts operate more quietly, with less vibration, making them ideal for noise-sensitive or precision applications.

- Belt drives require less maintenance and lubrication but may have a shorter lifespan compared to chains.

- Chains are more susceptible to rust and wear, requiring regular lubrication, while modern belts resist environmental damage.

- Installation and replacement of belts are quicker and simpler, reducing downtime, whereas chains need more maintenance and frequent adjustments.

Efficiency and Power Transmission Capabilities

When it comes to efficiency and power transmission, chains generally outperform belts because they can handle higher loads with less slip. Chains are made from rigid materials that offer less stretch, ensuring consistent power transfer even under heavy demands. Their material flexibility is minimal, which contributes to their superior performance in demanding applications. Additionally, proper lubrication and maintenance are essential to maximize the lifespan and efficiency of chain drives. Power transmission This makes them ideal for situations requiring maximum power transfer and precision. If your priority is efficiency and handling heavy loads, chains are the smarter choice, despite their less flexible and less visually appealing appearance. Durability and strength Properly maintained chains can also last longer in rigorous environments, further emphasizing their suitability for heavy-duty tasks.

Maintenance and Durability Factors

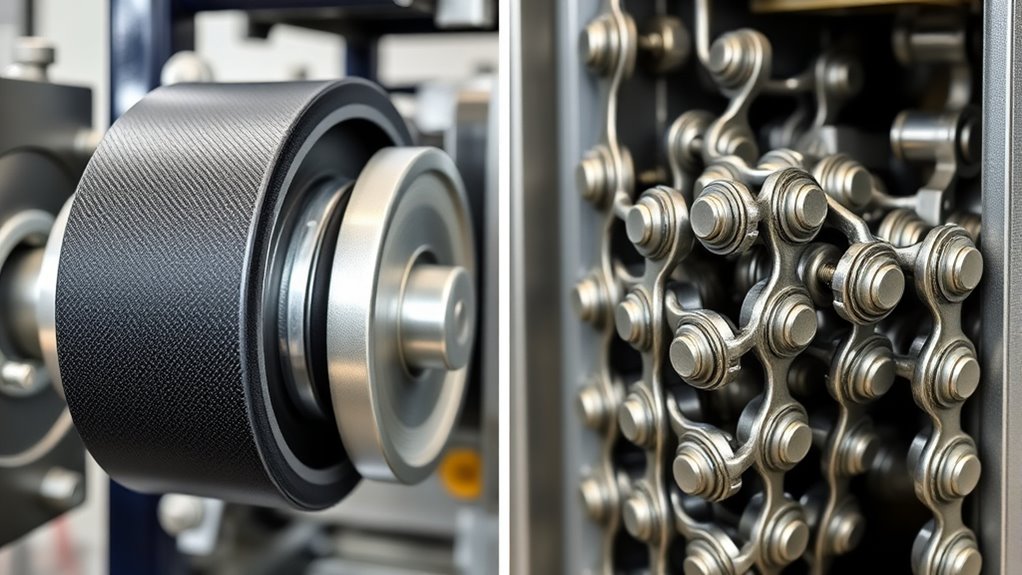

Maintenance and durability are critical factors to contemplate when choosing between belt drives and chains. Belt drives generally require less lubrication, which simplifies maintenance and reduces mess, but you still need to check tension regularly. Kia Tuning options often include upgraded belts for enhanced performance and longevity. Additionally, belt materials such as reinforced synthetic compounds can improve resistance to wear and environmental factors, with advancements in synthetic belt technology further extending their lifespan.

Furthermore, chains demand more frequent lubrication to prevent wear and ensure smooth operation. Corrosion resistance is also essential; chains are often more susceptible to rust if not properly treated or lubricated, especially in humid environments. Proper chain maintenance, including regular cleaning and lubrication, can extend lifespan and performance.

Belts, especially those made from synthetic materials, tend to resist corrosion better and withstand harsher conditions with less upkeep. Overall, belts typically offer lower maintenance needs and improved durability in corrosive environments. Modern belt designs incorporate advanced materials that further enhance their lifespan and resilience.

Synthetic belts resist corrosion and endure harsh conditions with minimal maintenance.

While belts excel in reducing maintenance, chains may need more attention but can handle heavier loads and tougher conditions if properly maintained.

Cost Implications and Budget Considerations

While belts generally require less ongoing maintenance than chains, their initial costs and long-term expenses can considerably influence your budget. Belt drives often have higher material costs upfront, especially if you choose premium materials like reinforced rubber or specialty polymers. This means your initial investment can be significant compared to chains, which tend to be more affordable initially.

However, chains usually require more frequent lubrication and replacement, adding to long-term costs. When considering material costs, think about durability and replacement frequency. If your project demands a lower initial investment, chains might be more budget-friendly.

But if you prioritize longevity and reduced maintenance, investing in belts could save you money over time despite their higher upfront expense. Always weigh material costs against long-term savings to make the best financial choice.

Noise Levels and Vibration Characteristics

Belt drives generally operate more quietly than chains, making them a preferable choice in environments where noise reduction is important. They produce less vibration, which helps minimize operational noise and provides smoother performance. This reduction in vibration also helps prevent unnecessary wear on the system components, leading to increased longevity. Additionally, Silky tantrums and pet antics during family photoshoots often create amusing and memorable moments. Chains tend to generate more sound due to metal-to-metal contact and their inherent tension fluctuations. Furthermore, the noise levels of belt drives make them suitable for settings requiring minimal disruption. If noise reduction is a priority for your setup, belt drives offer a significant advantage. Their quieter operation also creates a more comfortable environment, especially in settings like workshops or residential areas. Understanding industry trends can further help in selecting the most appropriate drive system for your needs. Moreover, considering maintenance requirements can influence the overall efficiency and lifespan of your drive system.

Suitability for Different Applications

Choosing between belt drives and chains depends heavily on the specific application.

For material compatibility, belts work best with smooth, clean surfaces and are less likely to cause damage, making them suitable for delicate or precision equipment.

Chains, on the other hand, handle high loads and harsh environments, making them ideal for heavy-duty machinery.

Aesthetic considerations also matter; belts offer a cleaner, more streamlined appearance, which is desirable in visible or consumer-facing setups.

Chains tend to be bulkier and more industrial-looking, fitting rougher environments better.

Your choice should align with the operational demands, material interactions, and visual requirements of your application.

Ultimately, understanding these factors guarantees you select the most suitable drive system for your needs.

Installation and Replacement Ease

Installing and replacing belt drives is generally straightforward and quick, thanks to their simple design and flexibility. Unlike chains, belts don’t require lubrication, which simplifies maintenance and reduces downtime. A properly tensioned belt ensures optimal performance and prevents slippage, making installation easier and more reliable. You’ll find that aligning the pulleys with precision is vital to guarantee smooth operation and longevity, but the process tends to be easier due to the belt’s flexibility. When replacing a belt, you often only need to loosen a few bolts and slide the belt off or onto the pulleys. This ease of installation minimizes effort and time. Overall, belt drives make routine replacements and adjustments more manageable, especially for those with limited technical experience. Their user-friendly nature makes them an attractive option for many applications where quick installation and minimal upkeep matter.

Frequently Asked Questions

Which Type Offers Better Resistance to Environmental Elements?

When considering resistance to environmental elements, you’ll find that belt drives generally offer better corrosion resistance and weather durability. They’re often made from materials like rubber and reinforced fabrics that withstand moisture, dust, and temperature changes better than chains.

Chains are more prone to rust and require regular lubrication, making them less ideal for harsh outdoor conditions.

How Do Belt Drives and Chains Compare in Weight?

When it comes to weight, you’ll find that belt drives generally weigh less than chains because of their lighter materials like rubber and fabric. This makes installation weight easier and less cumbersome.

Chains, on the other hand, tend to be heavier due to metal construction, which adds to overall material weight.

Can Either System Be Customized for Special Machinery?

Yes, you can customize either system for special machinery. Belt drives offer material flexibility, enabling you to choose from various materials like rubber, polyurethane, or fabric, which helps tailor their properties.

Chains provide design adaptability with different link types and sizes. By selecting appropriate materials and configurations, you can optimize either system to meet specific operational needs, ensuring better performance and longevity for your special machinery.

What Are the Typical Lifespan Differences?

Imagine your machinery’s lifespan as a story of resilience. Chains often outlast belts, typically lasting 3-5 years with proper lubrication, while belts might need replacing every 2-4 years.

Chains require regular lubrication but produce less noise, making them quieter over time. Belts are maintenance-light but can wear faster, especially under high tension.

Your choice impacts longevity, noise levels, and maintenance, shaping your machine’s performance story.

Which Requires Less Downtime During Maintenance?

You’ll find that belt drives generally require less downtime for maintenance because they don’t need lubrication, unlike chains.

Belt drives also tend to produce lower noise levels, making ongoing maintenance easier and less disruptive.

You’ll spend less time adjusting or replacing belts, which means you stay productive.

Conclusion

Choosing between belt drives and chains is like picking the right tool for a job—you need to evaluate your specific needs. Belts offer quiet, smooth operation, while chains provide durability for heavy-duty tasks. Think about maintenance, cost, and application demands. Ultimately, selecting the right drive system ensures efficient power transmission and long-term reliability, much like a finely tuned instrument that performs flawlessly under the right conditions. Your choice shapes your equipment’s performance and lifespan.