When working on your vehicle, it’s key to know the proper torque specs for common components like wheel lug nuts, engine bolts, and suspension parts. Using the correct torque guarantees safety, prevents damage, and helps parts last longer. Always follow the manufacturer’s recommended values and tighten in the proper sequence. If you want to get your torque just right and avoid future issues, there’s more to learn that can make a big difference.

Key Takeaways

- Different vehicle components, such as wheels, engine parts, and suspension, have specific torque specifications from the manufacturer.

- Always refer to the vehicle’s service manual for exact torque values for each component.

- Critical components like cylinder head bolts and crankshaft pulleys require precise torque to prevent damage.

- Using a torque wrench ensures proper tightening according to the recommended specifications.

- Over-tightening or under-tightening critical parts can lead to component failure or safety hazards.

Have you ever wondered why torque specs are so critical when working on your vehicle? Proper torque ensures that components are tightened to manufacturer specifications, preventing damage and ensuring safety. One key aspect of this process involves understanding bolt patterns and following the correct torque sequence. When working on parts like wheels or engine components, knowing the bolt pattern helps you arrange the bolts correctly, ensuring even load distribution. For example, wheel bolts are often arranged in a specific pattern—such as a 5-lug or 6-lug pattern—that aligns with the hub. Matching the bolt pattern precisely is essential to avoid uneven stress or wobbling, which can cause vibrations or even damage the hub. Once you’ve confirmed the bolt pattern, the next step is to tighten the bolts in the proper sequence.

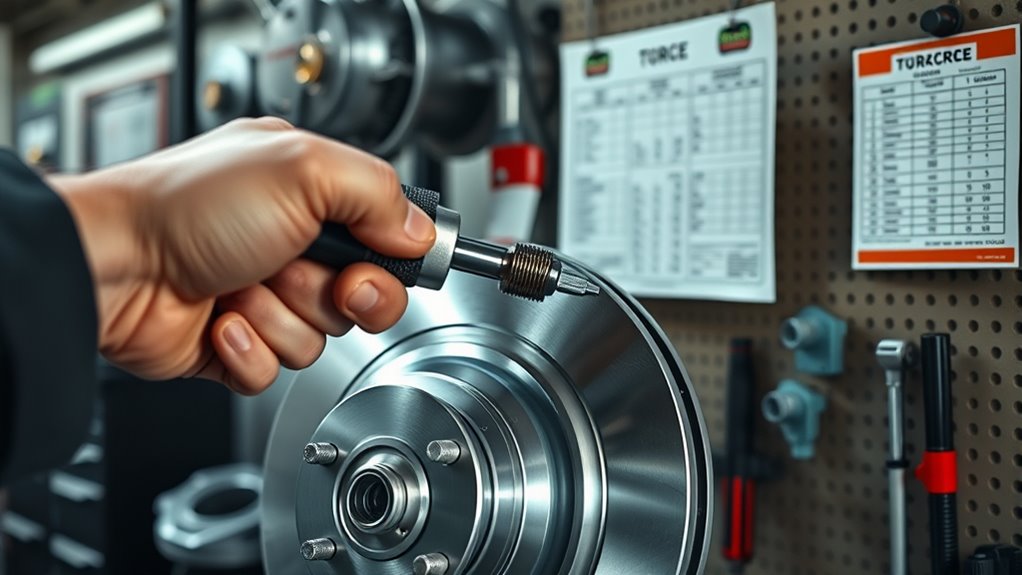

The torque sequence is a set of prescribed steps that guides you on the order in which to tighten bolts. Typically, you start by tightening bolts in a crisscross or star pattern, moving from the center outward. This method ensures even pressure across the component, helping prevent warping or misalignment. Ignoring the torque sequence can lead to uneven tightening, which might cause parts to sit improperly or develop stress cracks over time. For instance, when installing a wheel, following the recommended torque sequence and tightening each bolt gradually to the specified torque value guarantees a secure fit. It’s important to use a torque wrench during this process, as tightening bolts by feel alone can lead to over- or under-tightening, both of which compromise safety and part longevity.

Always refer to your vehicle’s service manual for the exact torque specs and the recommended sequence for each component. These specifications are tailored to ensure peak performance and safety. When tightening bolts, especially on critical components like suspension or engine parts, adhere strictly to these guidelines. Remember, going too tight can stretch or break bolts, while too loose can cause components to loosen over time. Using the correct torque specs and sequence also helps protect your vehicle’s warranty and prevents costly repairs down the line. So, whether you’re replacing brake rotors, installing new wheels, or servicing the engine, paying close attention to bolt patterns and torque sequences is essential. It’s the difference between a safe, reliable repair and one that might lead to problems down the road. Additionally, understanding the importance of precision in tightening can further enhance your maintenance practices and vehicle safety.

Frequently Asked Questions

How Do I Find the Correct Torque Specs for My Specific Vehicle?

To find the correct torque specs for your vehicle, check the torque chart in your vehicle’s service manual or online resources. Always follow the manufacturer guidelines, which provide precise torque values for each component. You can also visit the manufacturer’s website or consult a trusted repair manual. Using the right torque specs guarantees safety and prevents damage, so double-check these details before tightening any parts.

What Tools Are Best for Achieving Accurate Torque Measurements?

You’ll want a good torque wrench to get accurate measurements—think of it as your vehicle’s precision tool. Look for one with adjustable settings and verify it’s calibrated regularly using calibration tools to keep it reliable. A quality torque wrench prevents over-tightening or under-tightening, saving you time and potential damage. Investing in a dependable tool makes your work smoother and gives you confidence that every bolt is just right.

Can Over-Tightening Cause Damage to Components?

Over-tightening risks damaging components by putting excessive stress on bolts, nuts, and parts, which can lead to cracks, warping, or even failure. When you tighten too much, you risk stripping threads or breaking components, causing costly repairs. Always follow the recommended torque specs to avoid component damage. Using a torque wrench guarantees you apply the correct amount of force, preventing over-tightening and protecting your parts during assembly or maintenance.

How Often Should I Recheck Torque Settings After Installation?

You should recheck torque settings after installation within the first 50 to 100 miles of use, as part of your maintenance schedule. It’s also wise to periodically verify torque calibration, especially if you notice any vibrations or unusual performance. Regularly inspecting and adjusting torque guarantees components stay secure, preventing damage from over-tightening or loosening over time. This proactive approach keeps your equipment running safely and efficiently.

Are Torque Specs Different for New Versus Used Parts?

You might think torque specs are the same for new and used parts, but don’t be fooled—they’re worlds apart! Because of wear and tear and manufacturing differences, used parts often need different torque settings to prevent damage or failure. Always check the manufacturer’s guidelines for each component, as tightening the same way on worn parts can lead to catastrophic issues, unlike fresh, untouched components that stick to standard specs.

Conclusion

Understanding torque specs is essential for proper assembly and safety. Did you know that over 30% of vehicle failures are due to improper torque application? By following the recommended torque specs for common components, you guarantee durability and prevent costly repairs. Keep a torque wrench handy and double-check your work. Proper torque not only keeps your vehicle running smoothly but also extends its lifespan. Stay precise, stay safe, and keep your components secure.