To guarantee your hub bearings perform well and last longer, you should regularly check for signs of wear like grinding noises, wheel play, or vibrations. Proper wheel alignment and timely brake rotor replacements help prevent uneven bearing stress. If you notice issues, inspect and adjust the bearings following manufacturer guidelines. Performing these maintenance steps keeps your vehicle safe and smooth. Keep studying further to learn detailed procedures and tips for effective hub bearing service.

Key Takeaways

- Regularly inspect hub bearings for noise, play, or vibration to detect wear early.

- Ensure proper wheel alignment to prevent uneven bearing wear and extend component life.

- When replacing brake rotors, check and service hub bearings to prevent damage from uneven braking forces.

- Follow manufacturer guidelines for bearing adjustment and lubrication to maintain optimal performance.

- In harsh environments, perform more frequent inspections to mitigate accelerated component deterioration.

Have you ever wondered how to guarantee your vehicle’s hub bearings stay in top condition? Proper maintenance is vital, and understanding the connection between wheel alignment, brake rotor replacement, and hub bearing service can make all the difference. When your hub bearings are in good shape, your vehicle handles smoothly, and you avoid costly repairs down the line. Regularly inspecting and servicing your hub bearings ensures they perform at their best and last longer.

One of the first steps to maintaining healthy hub bearings is paying attention to wheel alignment. Misaligned wheels put uneven stress on bearings, causing them to wear out faster. If you notice your vehicle pulling to one side or uneven tire wear, it’s time to get a wheel alignment. Correct alignment not only extends the life of your tires but also reduces the strain on your hub bearings. When you keep your wheels properly aligned, you minimize vibrations and noise that can indicate bearing issues, preventing minor problems from becoming major repairs.

Proper wheel alignment extends tire life and reduces hub bearing stress.

Another vital aspect is ensuring your brake system is in good condition. Brake rotor replacement, for example, can indirectly impact your hub bearings. Worn or warped rotors can cause uneven braking forces, which leads to vibrations that travel through the wheel assembly and place additional stress on the bearings. If you’re experiencing pulsations or increased stopping distances, replacing the brake rotors promptly can help protect your hub bearings from unnecessary wear. Remember that during brake work, it’s a good idea to inspect the hub bearings for any signs of damage or looseness, as they often need to be serviced or replaced during brake rotor replacement.

Regular lubrication and inspection are key to keeping your hub bearings in prime condition. If you notice any grinding noises, wobbling, or excessive play in the wheel, these could be signs of worn bearings. Addressing these issues early prevents further damage to the wheel assembly and other suspension components. Additionally, wave and wind forces in the environment can accelerate the deterioration of exposed components like hub bearings, so regular checks are especially important in coastal or windy areas. When servicing your vehicle, always follow manufacturer recommendations for wheel alignment and brake maintenance, as these directly influence the longevity of your hub bearings. Neglecting these steps could lead to bearing failure, which is more costly and inconvenient to repair.

Frequently Asked Questions

How Often Should Hub Bearings Be Inspected or Replaced?

You should examine your hub bearings at least every 10,000 to 15,000 miles, or during regular vehicle maintenance. Replace them if you notice signs like noise, vibration, or excessive play. Follow the recommended inspection schedule and replacement intervals in your vehicle’s manual, as driving conditions can affect wear. Regular checks help prevent more serious issues and ensure safe, smooth operation of your vehicle.

Can Improper Adjustment Cause Wheel Vibration?

Improper adjustment of your hub bearings is like a crooked picture frame; it can definitely cause wheel vibration. When bearings aren’t set correctly, you might notice wheel imbalance and uneven tire wear, leading to a rough ride. Staying vigilant and ensuring proper bearing adjustment helps prevent these issues, keeping your wheels running smoothly. Regular inspections are key to catching problems early and avoiding costly repairs down the road.

What Are Signs of a Failing Hub Bearing?

If your hub bearing is failing, you’ll notice wheel noise, especially humming or growling sounds that worsen with speed. You might also feel bearing play, where the wheel feels loose or wobbly when you shake it. These signs indicate the bearing is deteriorating and needs inspection. Ignoring them can lead to more serious issues, so trust your senses and get your bearing examined promptly to ensure safe driving.

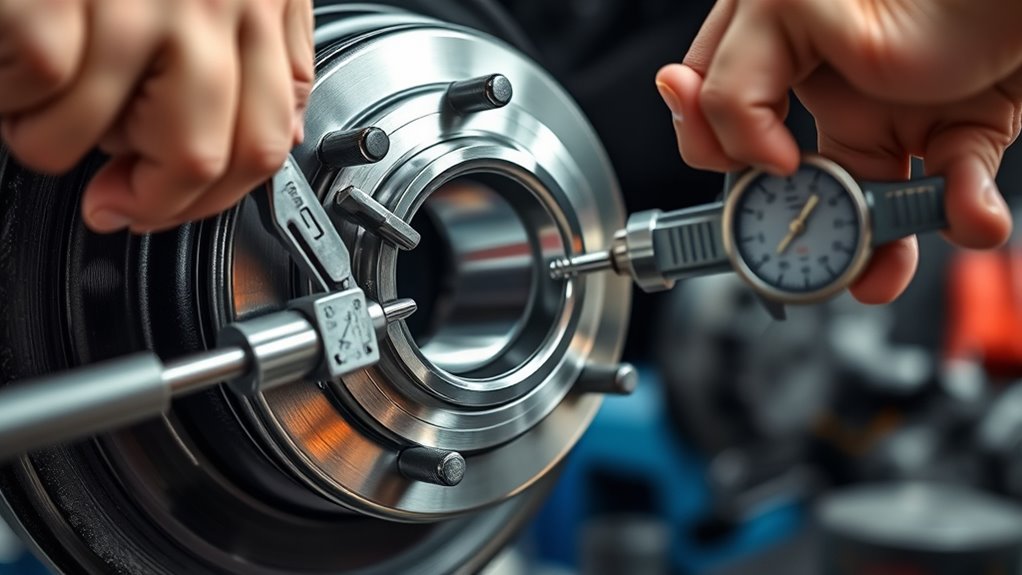

Is Special Equipment Needed for Hub Bearing Servicing?

You do need special tools and calibration equipment for hub bearing servicing. While basic hand tools might handle removal, proper adjustment or replacement requires precision, so don’t skip these essential items. Special tools ensure accurate torque and alignment, preventing future issues. Skipping this equipment risks improper installation, leading to uneven wear or bearing failure. Investing in the right tools guarantees safety, performance, and longevity of your hub bearing.

How Do You Reset the Hub Bearing Torque Specifications?

You reset the hub bearing torque specifications by first guaranteeing the bearing preload is correct, then using a torque wrench to tighten the hub nut to the manufacturer’s recommended torque. You should gradually tighten the nut while rotating the hub to maintain proper preload. Once you reach the specified torque, you can lock the nut in place. This process ensures the bearing functions correctly without excessive play or preload.

Conclusion

Now that you know how to adjust and service your hub bearing, you’re practically a mechanic superhero. With just a few simple steps, you can prevent your wheels from squealing like banshees and keep your ride smoother than a freshly paved highway. Imagine your car gliding effortlessly, like a rocket soaring through the stars, all because you took charge. So go ahead, master this skill—you’ll be the hero your car never knew it needed!