To avoid stripping bolts, always use the correct torque settings specified by the manufacturer. Invest in a quality, calibrated torque wrench and tighten fasteners in stages, applying steady pressure. Pay attention to thread condition and use thread lockers when needed. Regularly check your tools’ calibration and follow proper tightening techniques. Staying mindful during the process helps prevent damage and extends fastener life. Keep going, and you’ll discover more ways to keep your bolts secure.

Key Takeaways

- Always refer to manufacturer specifications or torque charts for accurate bolt tightening values.

- Use a properly calibrated torque wrench and double-check settings before tightening.

- Tighten bolts gradually in stages to prevent over-tightening and thread damage.

- Incorporate focused, mindful techniques to ensure consistent and precise torque application.

- Regularly inspect and maintain tools and fasteners to prevent damage and ensure longevity.

Understanding Torque and Its Importance

Have you ever wondered why proper torque settings matter? Correct torque calibration ensures bolts are tightened to the manufacturer’s specifications, preventing damage or failure. When you apply the right torque, you avoid over-tightening, which can strip threads or weaken components, and under-tightening, which risks loosening during use. Lubricant effects also play a vital role; applying lubricant reduces friction, so you need to adjust your torque accordingly to avoid over-tightening. Understanding how torque interacts with lubricants helps you achieve accurate tightening without damaging parts. Proper torque application maintains the integrity of assemblies, extends component lifespan, and ensures safety. Additionally, being aware of cultural impacts and community engagement can help you stay informed about the latest best practices in maintenance and repair. Incorporating industry standards into your procedures ensures consistency and reliability in your work. Mastering these fundamentals helps you prevent costly mistakes and guarantees your work is both reliable and effective, especially when considering material properties that influence torque requirements. Recognizing the influence of technological advancements can further enhance precision and efficiency in torque application. Furthermore, understanding equipment calibration is essential for maintaining accuracy over time and ensuring your tools provide consistent results.

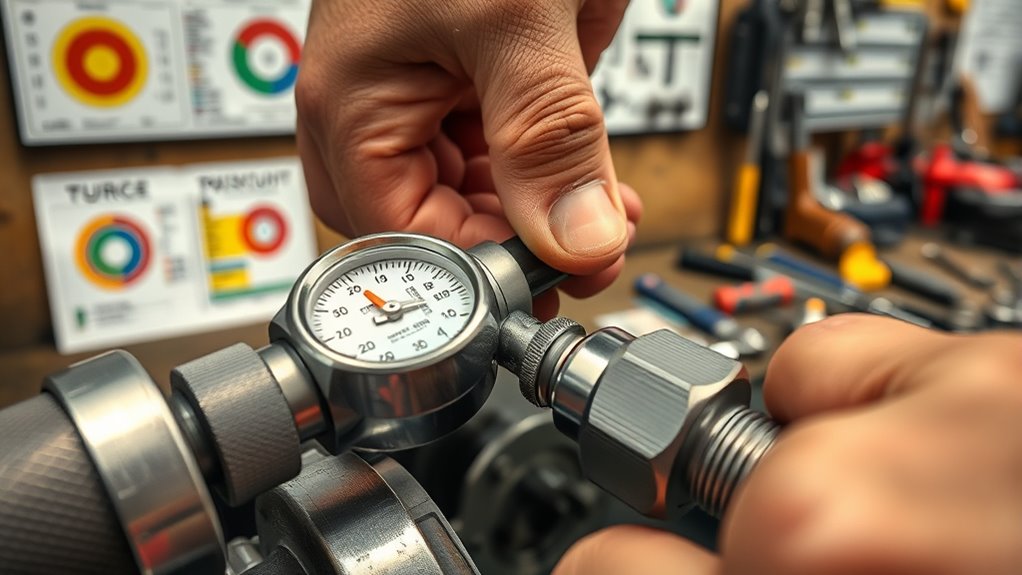

Common Tools for Measuring Torque

To guarantee accurate torque application, you need the right tools to measure it effectively. The most vital tool is a torque wrench, designed to apply a specific amount of force to fasteners. Torque wrenches come in various types, such as click, beam, and digital models, allowing you to choose what suits your needs best. Proper calibration is essential; without it, your readings might be off, risking over-tightening or stripping bolts. Calibration tools help you maintain your torque wrenches’ accuracy over time, ensuring consistent results. Regularly checking and adjusting your torque wrenches with calibration tools guarantees precise torque application. Investing in quality torque measurement tools and maintaining their accuracy is key to preventing damage and ensuring safety during assembly or repair tasks. Additionally, understanding the appropriate torque settings for different applications can help you avoid common issues like bolt stripping or insufficient fastening. Using the correct measurement techniques also ensures that you apply the right amount of force consistently across various projects. Being familiar with proper calibration procedures can further enhance the reliability of your torque measurements and extend the lifespan of your tools. Knowing how environmental factors such as temperature and humidity affect torque accuracy can also help you achieve more precise results.

How to Find and Use the Correct Torque Specifications

Finding the correct torque specifications guarantees you tighten fasteners properly without risking damage or failure. To do this, consult the manufacturer’s manual or trusted resources like OEM guides for exact torque specifications. Accurate fastener calibration is key—using properly calibrated tools ensures precision when applying torque. Always verify your torque wrench’s calibration regularly to prevent inaccurate readings. If available, use a torque chart specific to your fastener type or application, which simplifies selecting the right torque value. Remember, applying too much or too little torque can lead to fastener damage or component failure. Additionally, understanding the Paint Sprayer Zone can help you appreciate the importance of proper maintenance and calibration of your tools for optimal safety. Proper tool maintenance is essential for maintaining the accuracy of your torque wrench over time. Being aware of Gold IRA options can also be beneficial if you’re considering diversifying your investment portfolio as part of your financial planning. A well-maintained torque wrench not only extends its lifespan but also ensures consistent performance, which is crucial for precision fastening. By diligently finding and using the correct torque specifications, you ensure your fasteners are secure without risking stripping or weakening them. This careful approach saves time and prevents costly repairs later. Proper tool maintenance is essential for maintaining the accuracy of your torque wrench over time.

Step-by-Step Guide to Properly Tightening Bolts

Properly tightening bolts is essential to guarantee safety and reliability in any assembly. Start by inspecting the bolt pattern to ensure all bolts are correctly aligned before tightening. Select the right torque value based on the bolt’s thread pitch, since different pitches require different force levels to avoid damage. Use a calibrated torque wrench, set it to the specified torque, and position it properly on the bolt head. Tighten in stages, gradually increasing the torque to prevent uneven stress. Apply consistent pressure and avoid turning past the recommended torque. Always double-check your work with a torque wrench to ensure each bolt is tightened evenly. Understanding industry trends aids in selecting the appropriate torque settings for different applications. Additionally, being aware of headphone compatibility options can help ensure proper connection with various devices. Proper torque application also helps in preventing bolt damage and maintaining the integrity of the assembly. Following this step-by-step process helps prevent over-tightening or stripping, ensuring a secure, lasting fit. Incorporating proper maintenance practices can further extend the lifespan of assembled components.

Tips for Preventing Stripped Bolts and Over-Tightening

Preventing stripped bolts and over-tightening starts with understanding the importance of using the correct torque settings and tools. Always choose high-quality bolts, as inferior ones are more prone to damage. Applying the proper torque prevents over-tightening, which can strip threads or weaken the bolt. Consider using a thread locker when appropriate; it helps secure bolts without excessive torque, reducing the risk of stripping. Additionally, double-check your torque specifications and use a reliable torque wrench for consistency. Avoid guessing or relying on feel—precision matters. Regularly inspect bolts for signs of wear or damage and replace them if needed. The correct torque application is essential for maintaining bolt integrity and preventing damage. Proper torque calibration ensures your tools provide accurate readings, helping you avoid common mistakes. Incorporating mindfulness techniques such as focused attention while tightening can improve your accuracy and prevent over-tightening. Being aware of thread damage and how it can compromise fastener strength can further help prevent costly repairs caused by stripped bolts or over-tightening. Recognizing signs of bolt fatigue can alert you to potential failures before they occur. Taking these precautions ensures your fasteners stay secure, and you prevent costly repairs caused by stripped bolts or over-tightening.

Frequently Asked Questions

Can I Reuse Bolts After Stripping Them?

You might wonder if you can reuse bolts after stripping them. Generally, it’s not recommended because stripping can weaken the bolt, risking failure. Reusing stripped bolts risks stripping again and could compromise safety. To prevent stripping and ensure bolt reuse, always follow proper torque settings and use the right tools. If a bolt is stripped, replacing it is best for reliability and safety, preventing future stripping and ensuring secure fastening.

What Are the Signs of Over-Tightened Bolts?

You might think over-tightened bolts are obvious, but they often hide signs like bolt stretch or torque loss. When bolts are overtightened, they can stretch beyond their elastic limit, weakening the joint. Look for cracked or deformed bolts, or if the bolt feels unusually tight and then suddenly loosens under stress. Recognizing these signs helps prevent damage and guarantees your fasteners maintain proper tension, avoiding costly repairs.

How Do Temperature Changes Affect Torque Settings?

Temperature changes can considerably impact torque settings because of thermal expansion and material contraction. When temperatures rise, materials expand, which might loosen bolts if you don’t tighten them properly beforehand. Conversely, in colder conditions, materials contract, increasing tension and risking over-tightening. Always consider these effects when setting torque, and recheck torque after temperature fluctuations to guarantee bolts stay secure without stripping or loosening.

Are There Specific Torque Settings for Different Materials?

You should always consider material-specific torque because different materials need different fastener compatibility. For example, softer metals like aluminum require lower torque to prevent damage, while harder materials like steel can handle higher torque. Always check manufacturer guidelines for precise torque settings tailored to each material, ensuring your fasteners stay secure without stripping or damaging the parts. Proper torque helps maintain safety and longevity of your assembly.

How Often Should Torque Tools Be Calibrated?

Think of calibration intervals like a regular health check-up for your torque tools. You should calibrate them at least once a year, or more often if you use them frequently or in critical tasks. Regular calibration guarantees accuracy maintenance, preventing stripped bolts or loose connections. Keeping a schedule helps you stay confident in your tools’ performance, avoiding costly mistakes and ensuring safety with every use.

Conclusion

By applying the right torque, you’ll see your bolts snugly fit, like a lock clicking into place. Imagine your tools as precision instruments, guiding each turn with confidence. No more stripping or guesswork—just a smooth, satisfying tighten that holds strong. With practice, you’ll turn bolts effortlessly, like a craftsman shaping perfection. Keep these tips in mind, and soon, you’ll be the master of secure, damage-free fixes, ensuring every project stands the test of time.