To diagnose a mysterious click, start by listening carefully to pinpoint where it comes from—car locks, suspension, electronics, appliances, plumbing, tools, or musical instruments. Check for loose parts, debris, or wear and tear. Lubricate moving components or tighten loose screws. Recognize signs like vibration, expansion, or electrical switching. If you’re curious about specific fixes for each noise type, you’ll find helpful tips on how to identify and resolve these common issues below.

Key Takeaways

- Identify the source of the click by listening during specific actions, such as turning, bumping, or door locking.

- Inspect relevant components like suspension parts, door lock mechanisms, or electrical relays for wear, looseness, or damage.

- Understand common causes, such as debris, worn joints, or faulty actuators, to guide targeted troubleshooting and repairs.

- Use visual examination and diagnostic tools to detect early signs of component failure or interference.

- Perform regular maintenance, lubrication, and timely replacements to prevent recurring or escalating noises.

Clicking From Car Door Locks

Have you noticed a clicking sound coming from your car door locks? This noise usually originates from the lock mechanism inside your car door. When the lock mechanism functions improperly, it can cause the lock to cycle repeatedly, creating that distinctive click. Sometimes, debris or dirt inside the car door can interfere with the lock’s movement, leading to constant clicking. Other times, a malfunctioning actuator or a worn-out component causes the lock to attempt to engage or disengage repeatedly. To fix this, start by inspecting the lock mechanism for debris or damage. Lubricate the parts if necessary, and ensure the actuator is working correctly. If problems persist, replacing the faulty components might be your best option to silence the clicking and restore proper functionality. Regular maintenance and inspection can also prevent future issues with door lock mechanisms. Additionally, understanding how automation technology is integrated into vehicle systems can help in diagnosing complex electronic issues affecting door locks. Proper diagnostic tools and familiarity with electronic control systems can further aid in resolving persistent clicking problems. Recognizing signs of electronic malfunctions early can save time and prevent further damage.

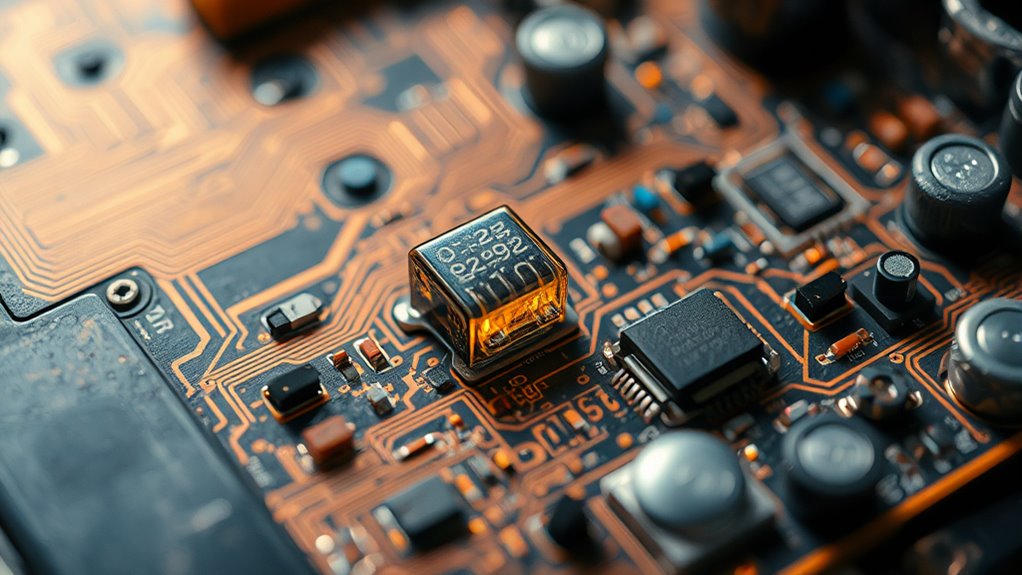

Ticking Sounds in Electronics

A ticking sound in your electronics is often caused by components switching or processing data, but it can also indicate underlying issues. You might hear it from devices with electronic timers or circuit relays, which use precise switching to control functions. While a gentle tick can be normal, persistent or loud ticking signals potential problems. High refresh rates in electronics can sometimes produce audible noises during rapid switching. Additionally, the presence of filter replacement indicators or similar alert systems might help identify when maintenance is needed to prevent such noises. Regularly inspecting circuit components can help catch early signs of wear or failure. Being aware of electronic noise sources can assist in diagnosing the origin of ticking sounds more effectively. For example, failing capacitors can produce irregular ticking sounds and may require replacement. Be alert to these signs:

- The ticking becomes louder or irregular, hinting at faulty circuit relays.

- The device intermittently powers on or off, suggesting timer malfunctions.

- Unusual heat or burning smell accompanies the ticking, risking damage.

Understanding these sounds helps you act quickly, preventing further damage and ensuring your electronics stay reliable. Don’t ignore persistent ticking—it’s your device’s way of warning you something’s wrong.

Snap or Click When Starting Appliances

When your appliance makes a sudden snap or click as it starts, it signals that a mechanical or electrical component is engaging or encountering resistance. This electrical clicking or noise during appliance startup often indicates a relay or switch activating. Sometimes, it’s normal, but persistent or unusual sounds could point to worn parts or electrical issues. Use this table to identify common causes:

| Cause | Possible Issue | Solution |

|---|---|---|

| Mechanical resistance | Faulty motor or relay | Replace worn parts |

| Electrical relay clicking | Dirty contacts or worn relay | Clean or replace relay |

| Capacitor problem | Faulty capacitor causing startup noise | Replace capacitor |

| Loose wiring | Connection issues | Tighten or repair wiring |

| Overloaded appliance | Excessive load causing stress | Reduce load or inspect components |

| Sound design techniques | Application of sound effects to enhance perception | Utilize layered and manipulated sounds for realism |

Popping Noises in HVAC Systems

Popping noises in HVAC systems can be startling, but they often point to specific issues within the ductwork or components. These sounds may signal temperature changes causing metal duct expansion or contraction, or moisture buildup. Regular HVAC filter maintenance helps prevent debris that can contribute to noise and system strain. Additionally, popping sounds might indicate a refrigerant leak, which requires prompt refrigerant leak detection to avoid system damage. Modern heat pumps incorporate noise reduction technology, making such sounds less common but still worth investigating. A sudden, sharp pop can also be a sign of pressure imbalance, which can cause components to vibrate or shift unexpectedly. Changes in system pressure are often linked to AI’s impact on regulation, highlighting the importance of monitoring system performance to ensure safety and efficiency. Properly installed and maintained systems can significantly reduce noise issues, ensuring quieter operation and greater comfort. Be alert to these signs:

- Sharp, sudden pops that disrupt calm

- Frequent noises despite proper filter maintenance

- Unusual odors or inconsistent cooling/heating

- Potential refrigerant leaks that can compromise system efficiency and safety

Addressing these issues early keeps your system running smoothly and quietly, preventing costly repairs and ensuring comfort. Don’t ignore the pops—they’re your system’s way of telling you something’s amiss.

Clicking in Your Vehicle’s Suspension

If you hear clicking sounds when you turn or go over bumps, your suspension might have a problem. These noises often come from worn-out components or loose parts, which can affect your vehicle’s handling. Regular maintenance can help prevent suspension clicks and keep your ride smooth. Additionally, understanding how different vehicle parts, such as suspension components, can help diagnose the source of the noise more accurately. Using diagnostic techniques can assist in pinpointing the exact cause of clicking noises, ensuring proper repairs.

Common Suspension Noises

A clicking noise in your vehicle’s suspension often indicates a problem that needs attention. This common suspension noise can be unsettling, signaling underlying issues that demand quick vehicle suspension troubleshooting. During suspension noise diagnosis, listen carefully when turning or driving over bumps, as these sounds often reveal worn components. Being aware of expert advice can help you understand the importance of addressing these issues promptly. Additionally, understanding how vehicle maintenance impacts suspension health can aid in preventing future problems. Proper suspension inspection can help detect early signs of wear and tear. Recognizing the signs of wear early helps prevent costly repairs and keeps your ride smooth. Be alert for:

- Sudden clicks when steering, hinting at joint issues

- Continuous tapping over rough terrain, suggesting loose parts

- Rapid clicks during turns, indicating worn CV joints

Ignoring these sounds can lead to further damage and unsafe driving conditions. Addressing suspension noises promptly ensures your vehicle stays safe and reliable. Recognizing the signs early helps prevent costly repairs and keeps your ride smooth.

Causes of Suspension Clicks

When you hear clicking sounds in your suspension, it usually points to specific mechanical issues that need attention. One common cause is suspension wear, which can cause components like ball joints or control arms to develop play, resulting in clicks during turns or bumps. A worn shock absorber can also be to blame, as it may not dampen movement properly, causing parts to shift and produce noise. Loose or damaged sway bar links can create clicking sounds when driving over uneven surfaces. Additionally, dried or corroded bushings can lead to metal-on-metal contact, generating noise. Addressing these causes promptly prevents further damage and ensures your suspension functions smoothly. Recognizing these signs helps you catch issues early before they escalate into costly repairs. Understanding suspension components can help diagnose the root cause of such noises more effectively. Proper maintenance and inspection are key to identifying potential problems before they become serious.

Preventative Maintenance Tips

Regularly inspecting your suspension components can help prevent clicking noises before they start. Staying on top of lubrication schedules ensures moving parts stay smooth and quiet, reducing wear that causes clicks. Regular component inspections allow you to catch issues early—like worn bushings or loose bolts—before they worsen. Don’t ignore sounds that seem minor; addressing them early saves money and hassle later. By maintaining your suspension proactively, you keep your ride comfortable and safe. Remember, consistent lubrication and inspections are your best defense against mysterious suspension noises.

- Feel confident knowing you’re preventing costly repairs.

- Enjoy a smoother, quieter ride every day.

- Keep your vehicle performing at its best longer.

Sharp Noises From Household Plumbing

Sharp noises from household plumbing often indicate air trapped in the pipes or high water pressure, both of which can cause banging or knocking sounds. If you notice these noises, check for faucet leaks that might be disrupting water flow and creating pressure issues. Sometimes, garden sprayers or other appliances can introduce air into the system, leading to loud banging. To fix this, turn off the main water supply and bleed the air from your pipes by opening faucets throughout your home. If faucet leaks persist, replace worn washers or tighten fittings. High water pressure can also cause pipe noise; consider installing a pressure regulator to maintain a steady flow and prevent future banging. Addressing these issues can markedly reduce the sharp noises disturbing your household.

Clicking in Power Tools

When your power tool clicks unexpectedly, it’s often due to battery issues, gear mechanism sounds, or loose components. Checking the battery’s charge and connection can usually solve the problem, but you should also listen for sounds indicating gear wear. Tightening or replacing loose parts may be necessary to get your tool running smoothly again.

Battery Issues

Ever wonder why your power tool clicks repeatedly when you try to operate it? It’s often due to battery issues like corrosion or a significant power drain. Corrosion on the terminals can disrupt the flow of electricity, causing the tool to hesitate or click. A weak or drained battery can’t supply consistent power, leading to frustrating noises and unreliable performance. When your battery isn’t functioning properly, you might feel the frustration building as your project stalls.

- Feel the disappointment of sudden power loss during vital moments

- Experience the anxiety of investing in a new tool that won’t start

- Recognize the frustration of troubleshooting repeated clicking without answers

Gear Mechanism Sounds

If your power tool is making a clicking sound during operation, it’s often a sign that the gear mechanism is experiencing issues. This transmission noise usually originates from the gear box, where worn or damaged gears can cause irregular engagement. When gears don’t mesh smoothly, you hear a repetitive clicking or grinding sound. Sometimes, a lack of lubrication or debris inside the gear box can also contribute to these noises. To fix this, stop using the tool and inspect the gear mechanism. Clean out any debris and apply proper lubricant if needed. If the gears are worn or broken, replacing them is essential to restore smooth operation. Addressing gear box problems promptly prevents further damage and prolongs your power tool’s lifespan.

Loose Components

A loose component inside your power tool can cause a clicking sound during operation. This often happens when parts aren’t secured properly, leading to unsettling noises. Think about the frustration of a loose cabinet or rattling furniture—it’s distracting and signals something’s wrong. When a component isn’t tight, it can shift unexpectedly, creating that annoying click. Check for loose screws or bolts in the housing, handles, or motor area. Fixing these can restore quiet operation and prevent further damage. Don’t ignore these sounds—they’re a warning sign.

- Feel the frustration of rattling furniture every time you use your tool.

- Experience relief when fixing that loose cabinet, ending unsettling noises.

- Regain confidence in your power tool’s reliability and safety.

Sudden Clicks in Musical Instruments

Sudden clicks in musical instruments often indicate a mechanical or electronic issue that needs quick identification. If your instrument suddenly makes a clicking sound, start by checking the instrument tuning. Incorrect tuning can cause parts to shift unexpectedly, resulting in clicks. For string instruments, pay close attention to string resonance; sometimes, a loose or improperly tensioned string creates a sharp noise when it vibrates against fretboards or pickups. In electronic instruments, ensure all cables and connections are secure, as loose wiring can produce intermittent clicks. Mechanical components like keys, bridges, or tuning pegs may also be the culprit if they stick or aren’t properly lubricated. Addressing these issues promptly helps maintain sound quality and prevents further damage.

Frequently Asked Questions

What Causes Random Clicking Sounds During Sleep or Rest Periods?

When you hear random clicking sounds during sleep or rest, it’s often due to the noise frequency and the source identification of the sounds. These clicks could come from your joints, muscles, or even your nervous system reacting to movement or changes in position. Identifying the source helps determine if it’s harmless or needs medical attention. Usually, these noises are normal, but persistent or loud sounds warrant a closer look.

How Can I Differentiate Between Normal and Problematic Clicking Noises?

You can differentiate between normal and problematic clicking noises by paying attention to sound frequency and noise duration. Normal clicks tend to have consistent, low frequency sounds that happen occasionally and last only a moment. Problematic noises, however, often have irregular or high frequency sounds that persist longer or occur more frequently. If the noise changes in pattern, intensity, or duration, it’s a good idea to consult a professional.

Are There Safety Risks Associated With Ignoring Clicking Sounds?

They say, “Better safe than sorry,” and ignoring clicking sounds can pose safety hazards you shouldn’t neglect. If a noise signals a mechanical issue or potential failure, it could lead to accidents or breakdowns, compromising your emergency preparedness. Always assess whether a click is normal or problematic, and don’t delay addressing possible safety risks. Staying alert ensures you’re prepared for unexpected situations, keeping you safe in the long run.

Can Clicking Noises Indicate Underlying Electrical or Mechanical Failures?

Clicking noises can definitely signal underlying electrical faults or mechanical wear. When you hear these sounds, it’s a sign that something’s not functioning properly, potentially leading to more serious issues if ignored. You should inspect the affected component promptly, as electrical faults might cause short circuits or fires, while mechanical wear could result in system failure. Addressing these issues early helps prevent costly repairs and guarantees your safety.

What Preventive Measures Can I Take to Avoid Clicking Issues?

To avoid clicking issues, you should prioritize preventive maintenance and routine inspections. Regularly check your equipment for loose parts, corrosion, or wear and tear that could cause noises. Keep moving parts lubricated and ensure all connections are secure. Address any early signs of trouble promptly, and follow the manufacturer’s maintenance schedule. These proactive steps help avert mechanical or electrical failures that often lead to clicking noises, keeping your system running smoothly.

Conclusion

Deciphering diverse, distracting noises can be intimidating, but with a little diligence, you’ll detect and dissolve dilemmas quickly. By understanding the subtle symphony of sounds—from car clicks to plumbing pops—you empower yourself to troubleshoot and tame troubling troubles. Tune into these tiny telltales, trust your tools, and take timely action. With patience and persistence, you’ll peaceably prevent problems, preserving your peace of mind and your prized possessions. So, listen closely, learn confidently, and keep your world working smoothly.